Using DIN charts correctly can prevent mistakes and ensure the smooth execution of our project

The Essential Guide to Using the DIN Chart

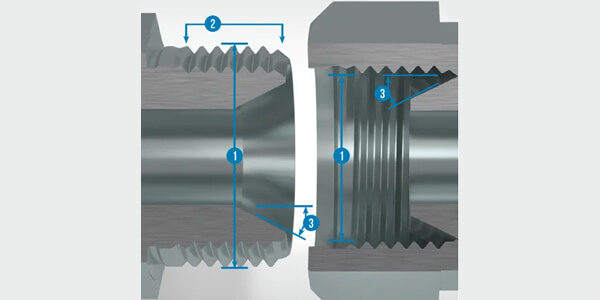

Using an O.D./I.D. caliper to measure the diameter of the threads. If you are measuring a used fitting and the threads are worn, consider replacing it as damaged threads are likely to leak.

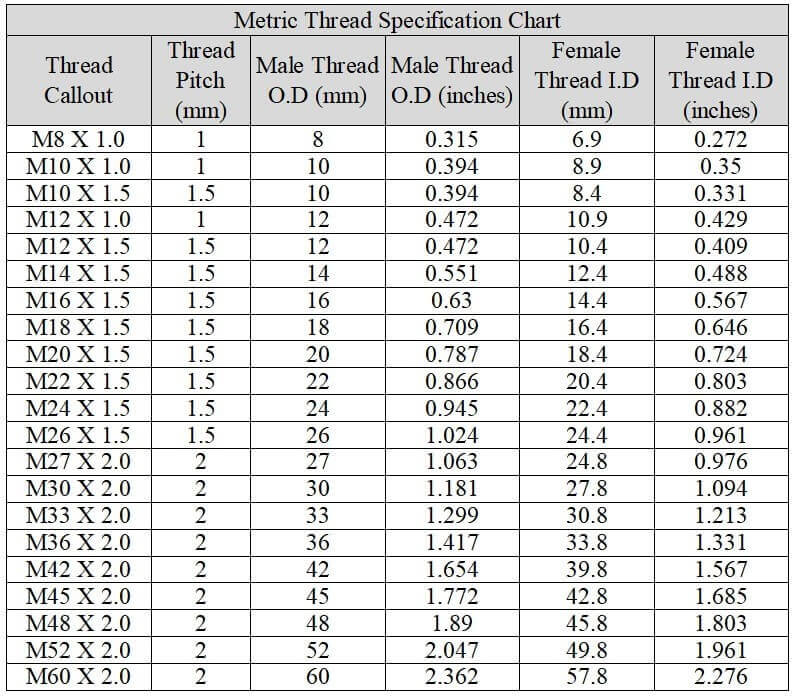

Placing the teeth into the fitting threads using a thread pitch gauge until it fits snugly to find an accurate measurement of the number of threads per inch. For metric fittings, measure the distance between the threads instead. Then, refer to a thread chart to confirm your measurements.

If the female port is tapered, use a gauge on the sealing surface to establish the seat angle. To ensure a proper measurement, the gauge must be parallel with the centerline of the fitting.

Refer to the corresponding DIN chart