Quality Control

QC Hydraulics has a strictly quality control manufacturing system.Our products are manufactured in accordance with international standards. Such as DIN/EN, ISO, SAE, BS & JIS.Of course, QC Hydraulics has gained ISO 9001:2015 certification.

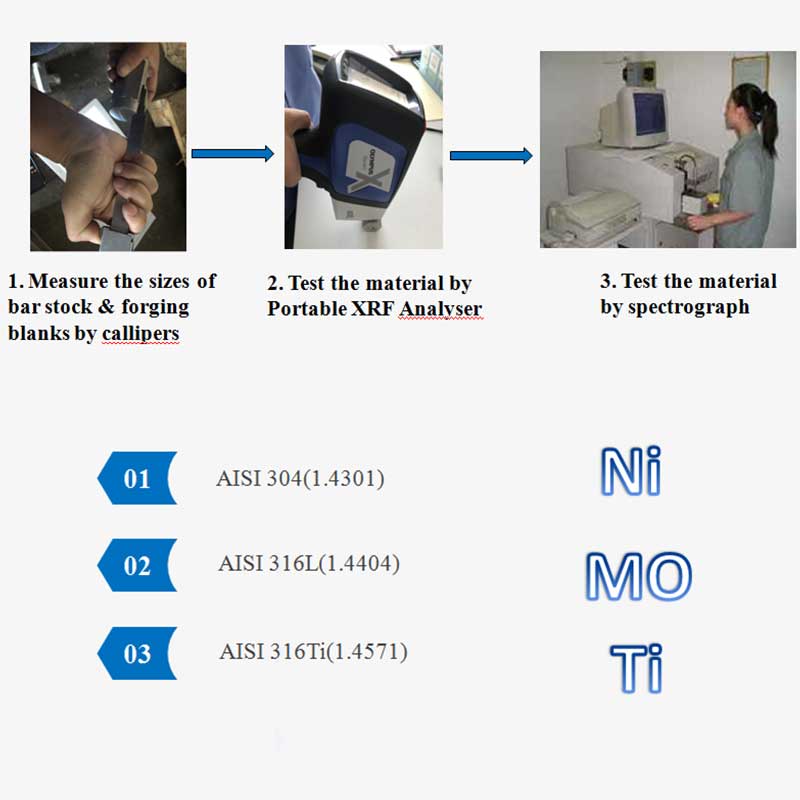

At QC Hydraulics, all dimensions, threads and tolerances are strictly in accordance with the approved drawings.The control of every article is rigorously enforced by our internal quality control department.

The Key Control of Production Process

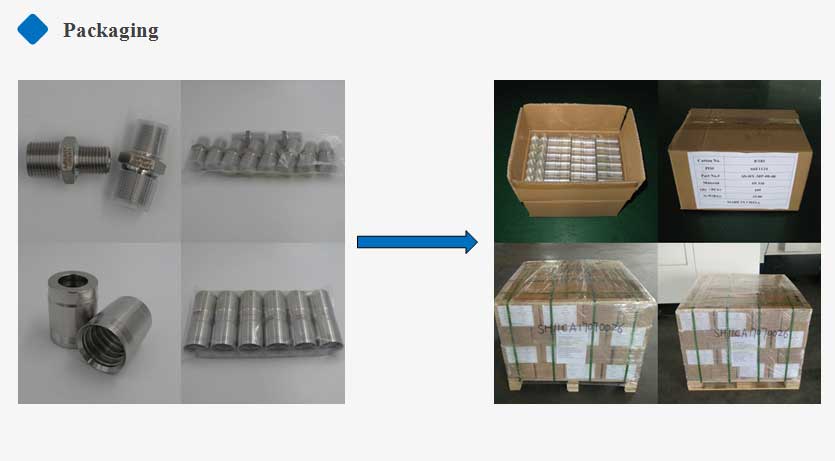

Packaging