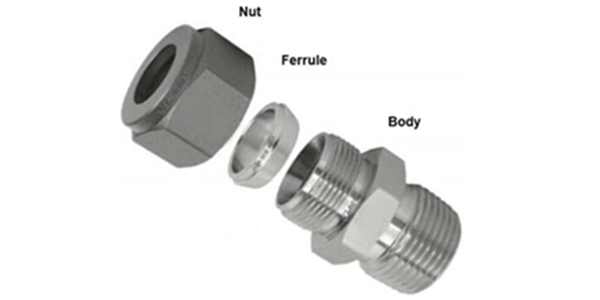

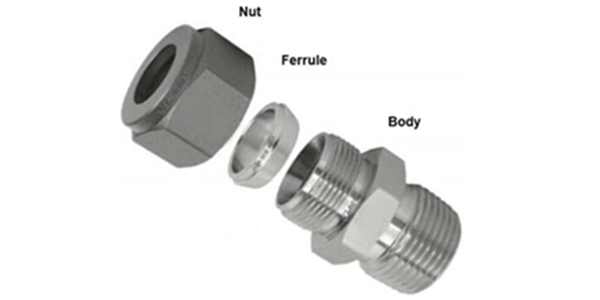

Compression tube fittings connect and seal tubes in a hydraulic or pneumatic system. They provide a strong and leak-proof connection and are crucial in applications with high pressures, vibration, and temperature changes. Compression fittings consist of three core components: a compression nut, a ferrule (or ferrules), and a body. To this day, there are two options to choose from when deciding on the best ferrule design for your application. We’re going to dig further into these two options to help inform your decision.

What is single ferrule fittings?

A single-ferrule compression fitting is made up of a single ferrule that grips the tubing and creates a leak-tight seal between the compression nut and the fitting body. In this case, the single-ferrule performs two functions simultaneously: it both seals the fitting and locks it in place. In medium-pressure applications, single ferrule fittings, also known as single or uni-ferrule fittings, are often used. Typically, the ferrule is constructed of a softer material, such as brass or stainless steel.

What is dual ferrule fittings?

A dual-ferrule compression fitting is made up of four components, two of which comprise the ferrule itself. A dual-ferrule, also known as twin-ferrules, comprises two separate ferrules that attach: a front ferrule and a back ferrule. In high-pressure applications, double ferrule fittings, also known as twin ferrule fittings or compression fittings, are commonly utilised. The front ferrule is normally composed of a softer material, such as brass, whereas the back ferrule is typically made of a tougher substance, such as stainless steel.

Single ferrule vs dual ferrule fittings

1)Design:

As already discussed, single ferrule fittings have one ferrule, while double ferrule fittings consist of two ferrules. This difference in design influences their applications and performance.

2)Operation pressure:

Single ferrule fittings are typically used for low-pressure applications up to 344 bar (5000 psi).

Within two-ferrule system, the double ferrule fittings distribute the pressure evenly, ensuring a better seal and grip, making them suitable for high-pressure applications (up to 689 bar or 10,000 psi). However, the pressure resistance may vary based on the material and design.

3)Vibration resistance:

The single ferrule has a compressed, lightweight back-end grip, which effectively isolates the seal point on the front end of the ferrule. This helps dampen vibration and allows any vibration to flow from the back of the ferrule through the nut/body of the assembly. Therefore, single ferrule fittings excel in applications where vibration is a concern.

Vibration can impact the dual ferrule fitting seals. The non-isolated grip of the back ferrule can experience concentrated stress. Therefore, double ferrule fittings may not be suitable in vibration and pulsation applications.

4)Reusability

Single ferrule fittings may not be as reusable as double ferrule fittings. The dual ferrule design allows component reuse, extending the life of the accessory.

5)Cost:

Single ferrule fittings are generally less expensive than double ferrule fittings. However, the potential costs associated with leaks, maintenance, and replacement must also be considered, especially in high-pressure or high-vibration applications where the cost of a single ferrule fitting may be higher

6)Applications:

Single ferrule fittings: Suitable for water treatment, pneumatic applications, instrumentation, and control systems, and plumbing and heating systems.

Dual ferrule fittings: Ideal for high-pressure environments, used in the oil and gas industry, chemical processing, laboratory and research applications, semiconductor manufacturing, and aerospace and aviation.

Conclusion

While single ferrule fittings might be suitable for low-pressure applications, less demanding environments, and situations where cost is a significant factor; double ferrule fittings might be more appropriate for high-pressure applications or where superior sealing performance and reusability are required. The decision should be made considering the specific requirements of the application.

QC Hydraulics company is a leading SS compression tube fittings manufacturer, please contact our teams to learn more about our SS Instrumentation Tube Fittings in mm, inches.