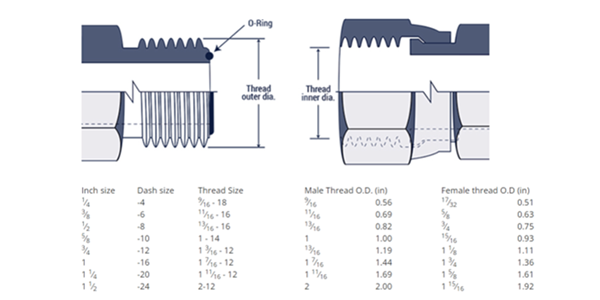

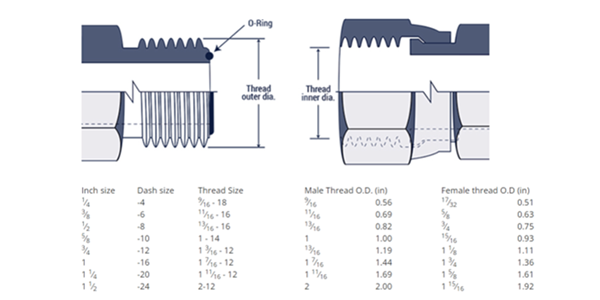

Made to SAE J1453 standard, ORFS connections are commonly manufactured in carbon, nickel plated carbon & Stainless steel and typically use Buna-N or Viton, 90 Durometer O-rings that seat into a groove in the face of the fitting.

O-ring face seal (ORFS) fittings are a highly popular and reliable choice in hydraulic and tube connections. Well designed ORFS connections provide a seal that is highly reliable due to its elastomeric seal and is one of the best choices for a leak-free connection. A seal is made when the O-Ring in the male contacts the flat face on the female. Fittings are intended for hydraulic systems where elastomeric seals are acceptable to overcome leakage and leak resistance is crucial. This connection offers the very best leakage control available today. The male connector has a straight thread and a machined flat face. The female has a straight thread and a machined flat face. The seal takes place by compressing the O-Ring onto the flat face of the female, similar to the split flange type fitting. The threads hold the connection mechanically.

The chart from Hydraulics Direct: please click here.

O-ring face seal fittings can eliminate leaks in hydraulic systems at operating pressures as high as 6,000 PSI. The fittings can be easily connected to a range of tubing grades by silver brazing. In addition, ORFS fittings can be disassembled and reassembled in the field to facilitate replacement of the O-ring or the entire assembly.

- ORFS Nut

- ORFS Sleeve

- ORFS Weld Plug

- NPTF Male ORFS Male

- ORFS Male 90° Adjustable Elbow

- ORB Male ORFS Male

QC Hydraulics can produce and supply all kinds of ORFS fittings which meet SAE J1453 standard and international standards, please contact our sales team to learn more about our ORFS fittings.