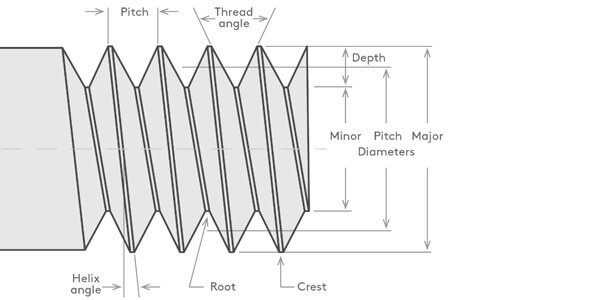

Metric thread callouts are fundamentally different because the thread pitch is specified instead of threads per inch or per mm. The thread pitch is the distance between each thread in mm. For example, an M10x1.5 (coarse) thread has a 1.5mm pitch, while an M10x1.25 (fine) thread has a 1.25mm pitch. To simplify metric thread callouts, the international (ISO) standard for metric threads eliminates the pitch callout on coarse threads. For example, the thread “M10” automatically means a coarse pitch, while any added pitch callout, such as M10x1.25, specifies a non-coarse pitch. The ISO standard for measuring thread sizes eliminates the need to memorize pitch callouts. This makes it more accessible for average citizens.

Metric vs Standard

The major difference between metric and standard is in how threads are specified. Standard fasteners are either Unified National Coarse Thread (UNC) or Unified National Fine Thread (UNT). Standard metric threads, meaning ISO metric threads in this case, are not specified this way, though they are comparable to UNC threads.

Standard metric screw threads are designated by pitch in millimeters (mm). This is the distance measured between the peaks of two adjacent threads. ASTM fastener standards measure threads by TPI: threads per inch. You literally just count the number of threads that cover a one-inch distance.

Some steps should be taken in order to ensure you have successfully identified the proper Metric thread:

- Identify if the thread is parallel or tapered

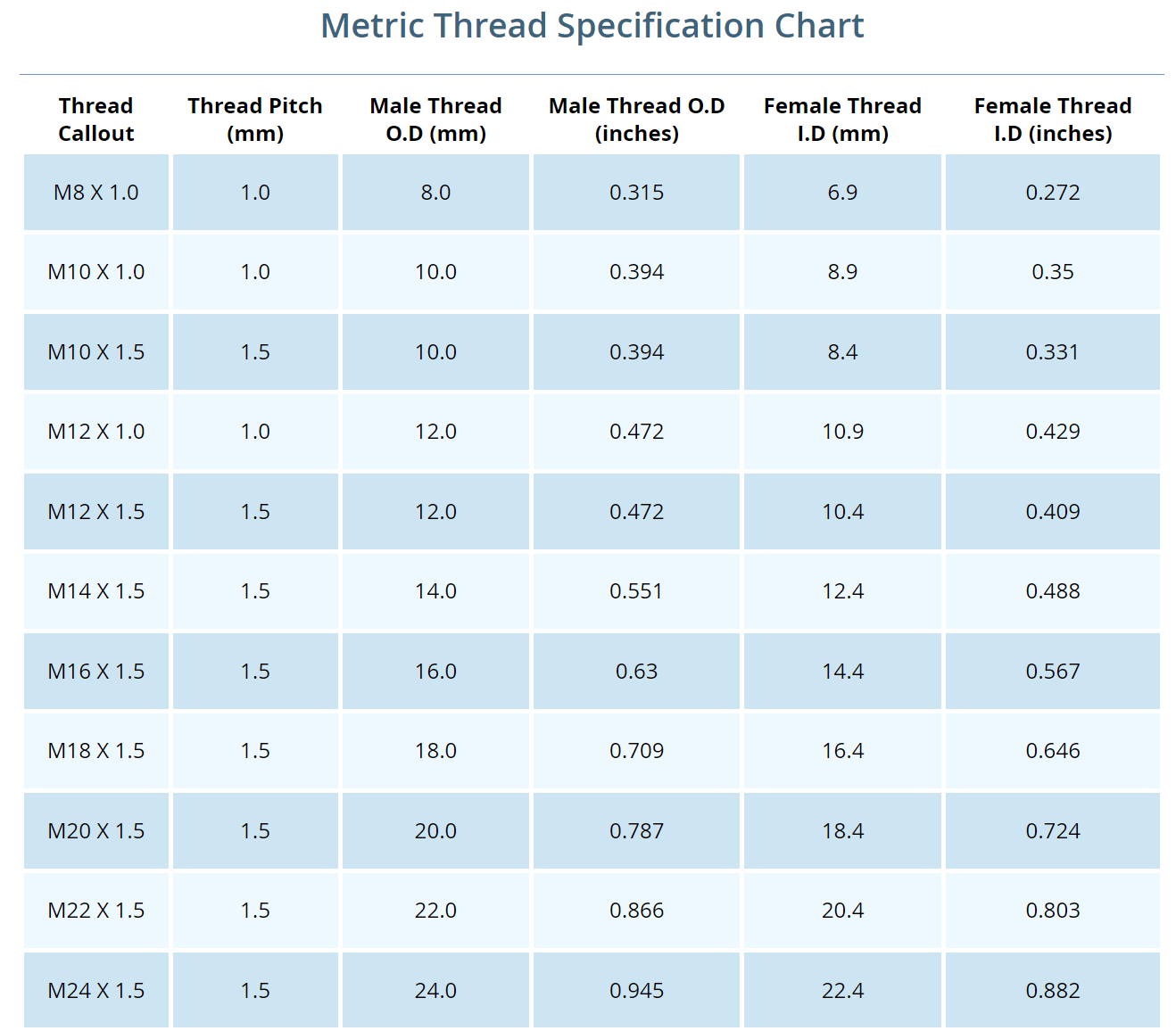

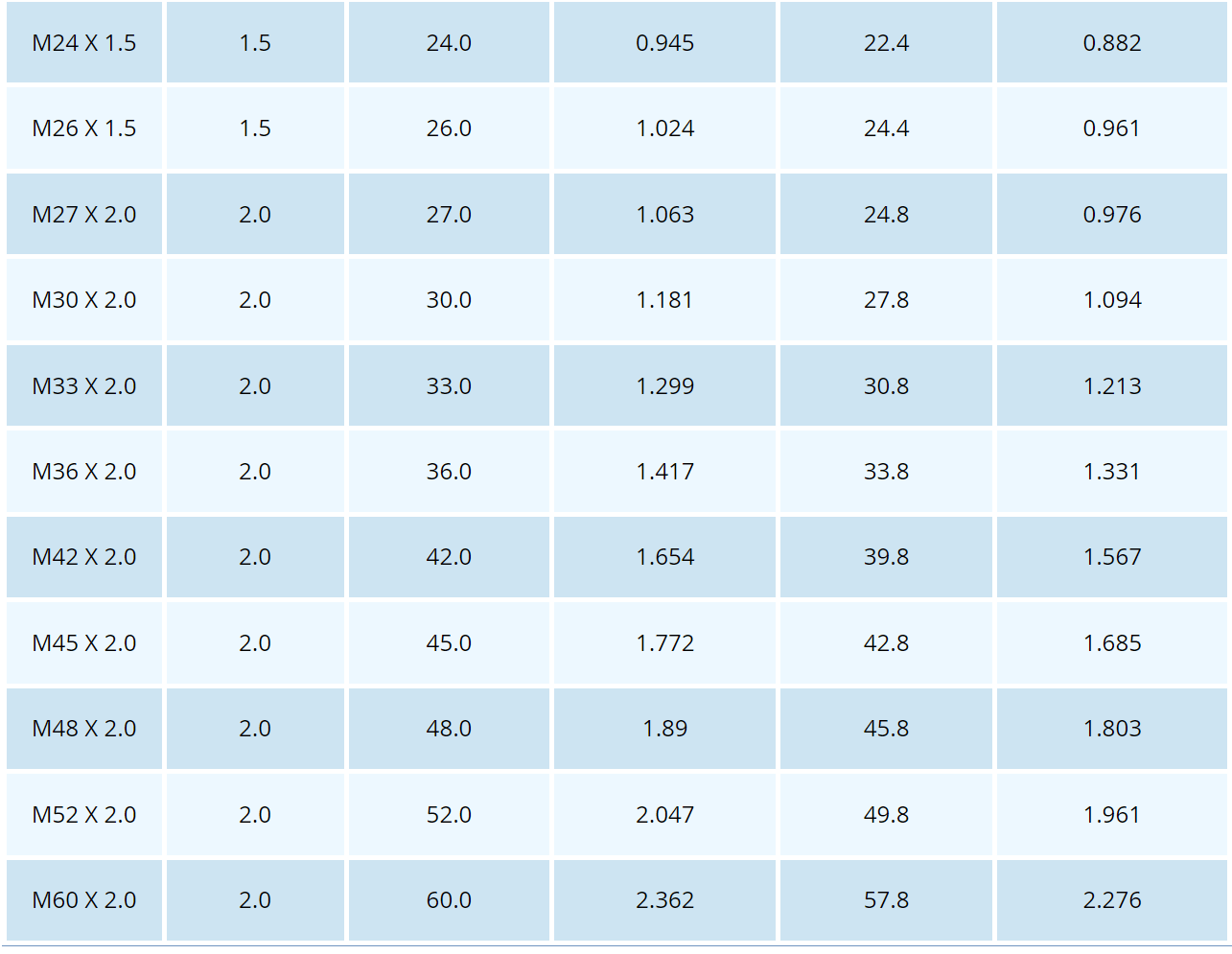

- Determine the thread pitch in mm using a thread gauge or calipers (typically 1.0, 1.5, or 2.0, but other sizes do exist)

- Determine the thread O.D (male thread) or I.D (female thread) using calipers.

- Find the closest match on the adjacent chart (thread O.D and pitch combine into a “thread callout” such as M12 x 1.5 indicating a 12mm O.D with 1.5mm pitch)