Flare fittings are a type of compression fitting used with metal tubing, usually soft steel and ductile (soft) copper. Tube flaring is considered to be a type of forging operation, and is usually a cold working procedure. The most common flare fitting standards in use today are the 45-degree SAE style, and the 37-degree style, also used with the JIC system. Today we will talk some more details about JIC and SAE thread.

What is JIC thread?

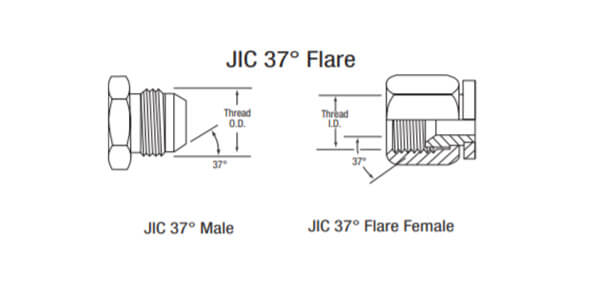

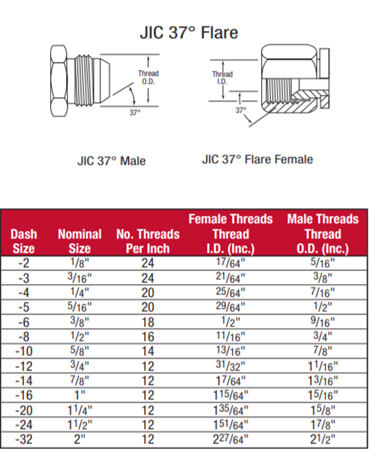

JIC fittings,defined by the SAE J514 and MIL-DTL-18866 standards,are a type of flare fittings machined with a 37-degree flare seating surface.JIC(Joint Industry Council)fittings are widely used in fuel delivery and fluid power applications,especially where high pressure(up to 10000 psi)is involved.

What is SAE thread?

SAE(SAE J512)stands for the Society of Automotive Engineers. SAE fittings are mostly used in refrigeration, automotive piping systems and other low-pressure applications. It’s common for copper tubes to be used with SAE threads. SAE Flare The SAE male and female halves both have a 45° flare seat.

In some ways,JIC fittings are identical to AN (Army-Navy) fittings, but are produced to less exacting tolerances and are generally less costly. SAE 45-degree flare fittings are similar in appearance, but are not interchangeable, though dash sizes 2, 3, 4, 5, 8, 10, 14, and 16 share the same thread size.Carefully measure the seat angle to differentiate.

If you have any questions about JIC and SAE fittings,please feel free to contact QC Hydraulics and get more details.