ISO 8434-1 fitting (as known as DIN 2353 in DIN standard) is the metallic tube connection for fluid power and general use with 24°cone connectors. It specifies the general and dimensional requirements for 24°cone connectors using cutting ring and O-ring seal cone suitable for use with ferrous and non-ferrous tubes with outside diameters from 4 mm to 42 mm inclusive.

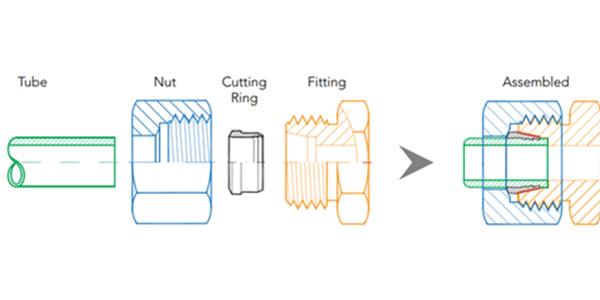

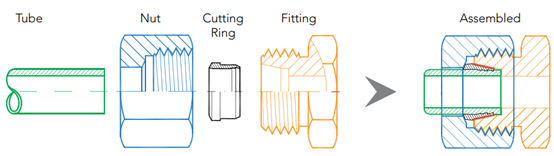

Construction

Fittings to ISO 8434-1/DIN 2353 comprise a body, a cutting ring and a tightening nut.

Pressure

According to different applications and different pressure ratings, there are three series of connector, designated by

⎯ LL, for extra light-duty, for low pressures (up to 100 bar) and 4 to 12 mm o.d. tube.

Example: lubrication, braking systems.

⎯ L, light-duty, for medium pressures (up to 400 bar) and 6 to 42 mm o.d. tube.

Example: machine tools, agricultural equipment.

⎯ S, heavy-duty. for high pressures (up to 630 bar) and 6 to 38 mm o.d. tube.

Example: hydraulic presses, public works equipment

Material

DIN 2353 metric stainless steel 1.4571 (316Ti) is the primary material for excellent corrosion resistance. Stainless steel 316Ti and sometimes other exotic materials are used in conditions with high acidity and elevated salt levels, such as offshore oil rigs. These materials provide a long service life, reducing the total cost of ownership and leading to lower maintenance costs.

Stainless steel 1.4571 (316Ti) DIN 2353 fittings are ideal for harsh environments, along with Monel and Inconel, and used in extreme conditions such as the presence of:

-Salt spray or saltwater submersion

-Acidic atmosphere

-Extreme heat or cold

-Physical shock

-Vibration

Carbon steel is also applicable in many common applications and provides very good corrosion resistance. For these applications, a specific zinc-nickel plating is applied that exceeds U.S. and international corrosion resistance standards– such as VDMA 24576 class K5. When tested to 1000 hours of exposure to salt spray zinc-nickel plated carbon steel, they should not show any traces of red or white rust, allowing them to present:

-Good paintability

-High levels of abrasion protection

-Very good temperature stability

-Low corrosion when in contact with stainless steels or aluminum

Applications and Industries

As with other hydraulic fitting thread styles, DIN metric bite-type fittings are widely used in industries and fluid power applications, such as:

-Agricultural equipment

-Construction equipment

-Industrial machines

-Oil & gas

-Drilling platforms

-Hydropower plants

-Railway technology

-Recycling equipment

-Shipbuilding

-Machine tools

-Wind turbines

-Material handling

-Mining equipment and hydraulic supports holding up the mine roof

DIN are the worldwide standardized metric thread, and is the most widely used fitting in Europe, surpassing any imperial (inch) thread style. Many OEMs are increasingly choosing DIN metric (along with O-ring face seal) due to their ability to withstand higher pressure ratings many of today’s applications require.

- DIN Nut

- DIN Cutting-Ring

- ED Seal DIN Fitting

- 90° Elbow DIN Swivel

- 90° Elbow DIN Union

- DIN Tee

QC Hydraulics can produce and supply all kinds of ISO 8434-1/DIN 2353 DIN tube fittings, please contact our sales team to get the correct fittings for your applications.