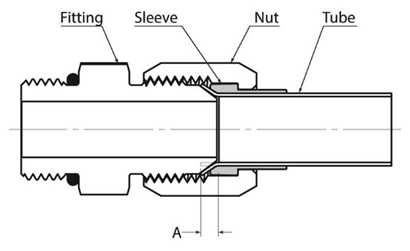

What is flared fitting?

A flare fitting has a tapered end that fits into a flared piece of tubing and is secured in place with a sleeve and flare fitting (threaded nut) to produce a pressure-resistant, leak-tight seal. The tubing must first be flared by inserting a flaring tool (typically a mandrel or rolling cone) using a cold working procedure.

Flared fittings provide significant design and performance characteristics as compared to pipe fittings and can be used with thin to medium wall tubing. In most hydraulic design applications, pipe fittings have long been replaced with flared fittings, particularly in military and aerospace equipment. In low to medium pressure applications, the most common connection type is a flared fitting. Single flare SAE 37° is the standard in most hydraulic systems. SAE standards for the maximum tube wall thickness must be followed before flaring the tube to match the fitting connection.

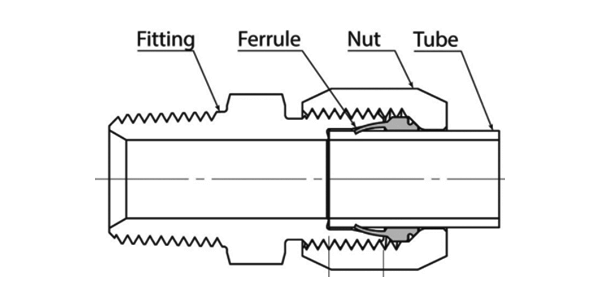

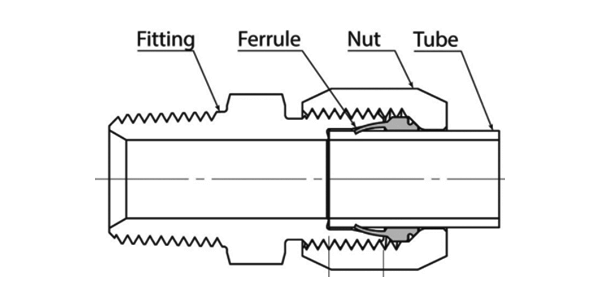

What is flareless fitting?

A flareless fitting also referred to as a compression fitting, uses a single ferrule and a nut to make a connection, eliminating the need for flaring. The nut and ferrule(s) slide over a tube with an OD that matches the ID of the receiving fitting. As the nut is tightened with the proper torque, the nut compresses the ferrule to the tube, thus providing a tight and leak-free seal.

Flareless fittings are common because they can be used with a wide variety of tubing types and because connections are easy to make. They require less time and care than flare fittings.

Flareless fittings are used extensively to connect tubing to threaded components, such as valves and tools. They are ideal for systems with high vibration, as they dampen vibration better than flare fittings do. They are also a better solution for thicker tubing, because the flareless fitting does not require the tube end to be flared.

When deciding whether you need a flared or flareless fitting, it is important to consider the application that you plan to use it for. Factors that can affect the decision should include the wall tubing size, pressure, amount of vibration, and stressors that the fittings will have to endure.

Please contact QC Hydraulics sales team to learn more about flared fittings and flareless fittings.