UN = Unified National Fixed Pitch Series

UNC = Unified National Coarse Series

These designations are defined in ANSI/ASME B1.1 with modifications defined in ANSI/ASME SAE AS8879. Here is a summation of the designation system defined in these standards:

The first designation is simply: UN. UN = Unified National. UN is used for a set of specific thread series which have uniform or constant threads-per-inch. The eight constant threads-per-inch (TPI) series are: 4-TPI; 6-TPI; 8-TPI; 12-TPI; 16-TPI; 20-TPI; 28-TPI; and 32-TPI. When a fixed series coincides with: C; F; or EF, the C; F; or EF take precedence.

Appended to the UN are several suffixes: C = Coarse; F = Fine; EF = Extra Fine; For ease of design, and improved size standardization, the writers of the ANSI B1.1 standard have established the Coarse, Fine and Extra Fine standardized series. Thus, if a design requires a coarse thread, the nominal major diameter is selected and then the coarse thread for that size can be identified within the standard and used in the design. Similar for fine and extra fine requirements.

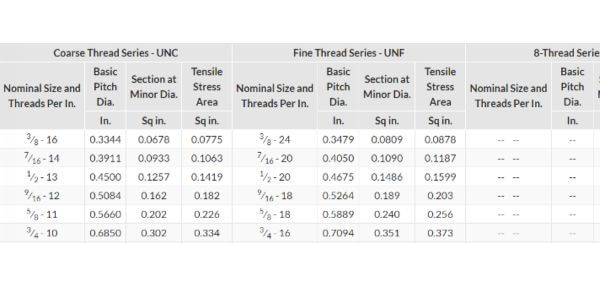

The UNC thread has less teeth of the same length, larger cross-section size of each tooth, and more suitable for bearing larger tensile force and impact force. UNC threading has also greater tolerances, better handles manufacturing and plating than other threading (such as UNF). Coarse thread series (M/UNC/UNRC) is generally used for mass production of threaded fasteners, such as bolts, screws, nuts, etc. It has unique advantages in some rough operation applications that require quick assembly or disassembly and are easy to produce corrosion and damage.

Please feel free to contact our team to learn more technical information of fittings.