Steel has been a driving force in industrial growth for over a century, contributing to advancements in various sectors. This influence extends to hose end fittings, crucial components in customized hose assemblies, particularly in hydraulic systems. In the realm of hose assemblies, the choice between carbon steel and stainless steel for hose end fittings holds significant importance, impacting performance and durability. Let’s dive into the intriguing differences between carbon steel and stainless steel, and discover how choosing the right one can impact the performance and durability of your hose assemblies.

Understanding Carbon steel & Stainless steel:

Carbon steel, primarily made from a blend of iron and carbon, is a fundamental material in manufacturing. Its composition varies, with carbon content ranging from as low as 0.3% to as high as over 2%. This variability leads to different grades of carbon steel, each with distinct properties. The higher the carbon content, the more durable and stronger the steel becomes, but it also increases its brittleness. Notably, carbon steel lacks the chromium present in stainless steel, which is a key factor in corrosion resistance.

Stainless steel, a prominent material in hose end fittings, is distinguished by its significant chromium content – at least 10%. This chromium inclusion is crucial for its well-known corrosion resistance. Additionally, elements like nickel, molybdenum, and nitrogen can be added to enhance specific properties. There are over 150 grades of stainless steel, but only a few are typically used in hose fittings. The 304 and 316 series are the most commonly used because of their high strength and corrosion resistance properties.

Differences Between Carbon Steel & Stainless Steel Hose Fittings:

1.Corrosion Resistance:

Stainless Steel: Stainless steel has excellent corrosion resistance, making it ideal for objects that are frequently exposed to moisture or corrosive substances.

Carbon Steel: Carbon steel corrodes easily, especially in high humidity environments or when exposed to chemicals. Protective coatings or treatments are often used to mitigate this risk.

2.Strength:

Stainless Steel: While stainless steel is strong, its strength can be slightly lower than that of carbon steel. However, certain stainless-steel alloys can offer comparable strength.

Carbon Steel: Carbon steel is renowned for its strength, making it suitable for applications where structural integrity is crucial.

3.Cost-Benefit Considerations

Stainless Steel: Stainless steel tends to be more expensive than carbon steel. However, the initial investment often pays off due to its durability and longevity, requiring less maintenance and replacement over time.

Carbon Steel: Carbon steel is more cost-effective initially, making it a popular choice for projects with budget constraints. However, ongoing maintenance costs should be factored in, particularly in corrosive environments.

4.Weight:

stainless steel fittings have thinner walls compared to carbon steel fittings, reducing weight and dimensions for the overall assembly.

Stainless Steel in Hose End Fittings Advantages:

1.Corrosion resistance: Ideal for environments exposed to chemicals or moisture.

2.Durability: Longevity is a hallmark, reducing the need for frequent replacements.

3.Temperature resistance: excellent performance in both high and low-temperature environments.

4.Applications: widely used in hydraulic systems where leakage prevention is critical. In industries like marine, chemical processing and food processing where corrosion is a concern.

How to choose the correct material hose end fittings?

Choosing between carbon steel and stainless steel hose end fittings involves a careful evaluation of factors such as physical conditions, cost, and availability. While carbon steel offers strength and cost-effectiveness, stainless steel provides superior corrosion resistance and a sleek finish. Tailoring the choice to the demands of your hose assembly ensures optimal performance and longevity.

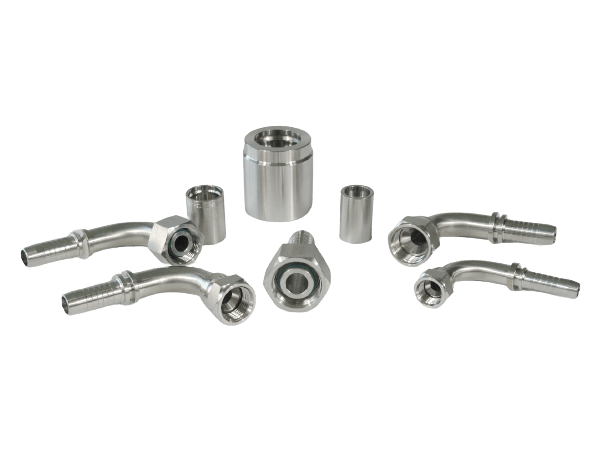

QC Hydraulics has a widely range of stainless steel hose end fittings, with all main threads in the market, made of high grade SS 304, SS 316L, SS 316Ti for different applications. Please contact our team to get more details of our fittings.

- SS Hose Crimp Fittings

- SS Two Piece Hose Fittings