In the field of hydraulic fittings and piping, two threads are international standards: the British Standard Pipe Thread (BSP) and the National Tapered Pipe Thread (NPT). These two thread systems have become the cornerstone of modern hydraulic applications and each has unique characteristics and areas of application.

BSP threads are the dominant standard in the United Kingdom, Europe, Asia, Australia, and many other countries.

Types of BSP Threads

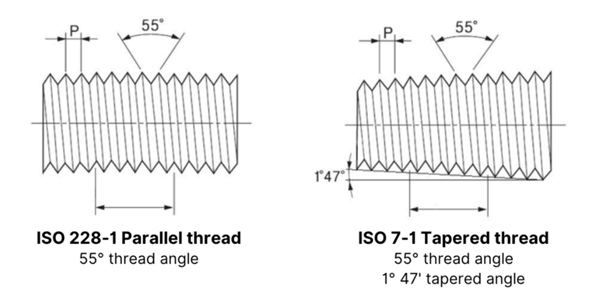

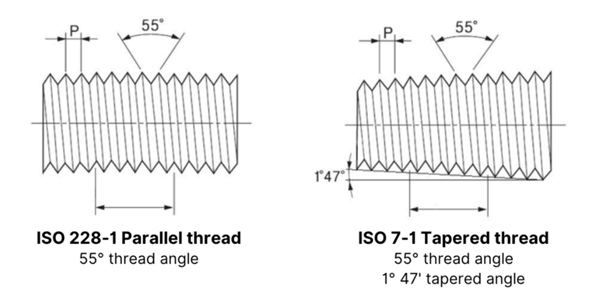

BSPP (British Standard Pipe Parallel): With parallel threads, BSPP offers a reliable and versatile option for various applications. It’s commonly used in low-pressure applications where a tight seal is required. Parallel threads can be called BSPP or GAS threads, abbreviated as “G“. They are threads designed for gases. The internal and external threads of a parallel thread are sealed with the help of an O-ring to prevent fluid leakage.

BSPT (British Standard Pipe Taper): Similar to NPT but with a 55-degree angle, BSPT threads provide a unique solution for specific needs. The tapered design allows for a more secure fit, making it suitable for high-pressure applications. BSPT male threads are R series threads, while the female threads are called Rc series threads. They form a metal-to-metal seal when sealing and do not require the use of O-rings, although sealants are sometimes required.

National Pipe Threads (NPT) are synonymous with quality and precision in the U.S. and Canada, and with a 60-degree angular taper, NPT threads have become the preferred choice for pressure calibration systems in North America. The standard has been a cornerstone of the hydraulic industry, reflecting a commitment to innovation and excellence.

Types of NPT threads

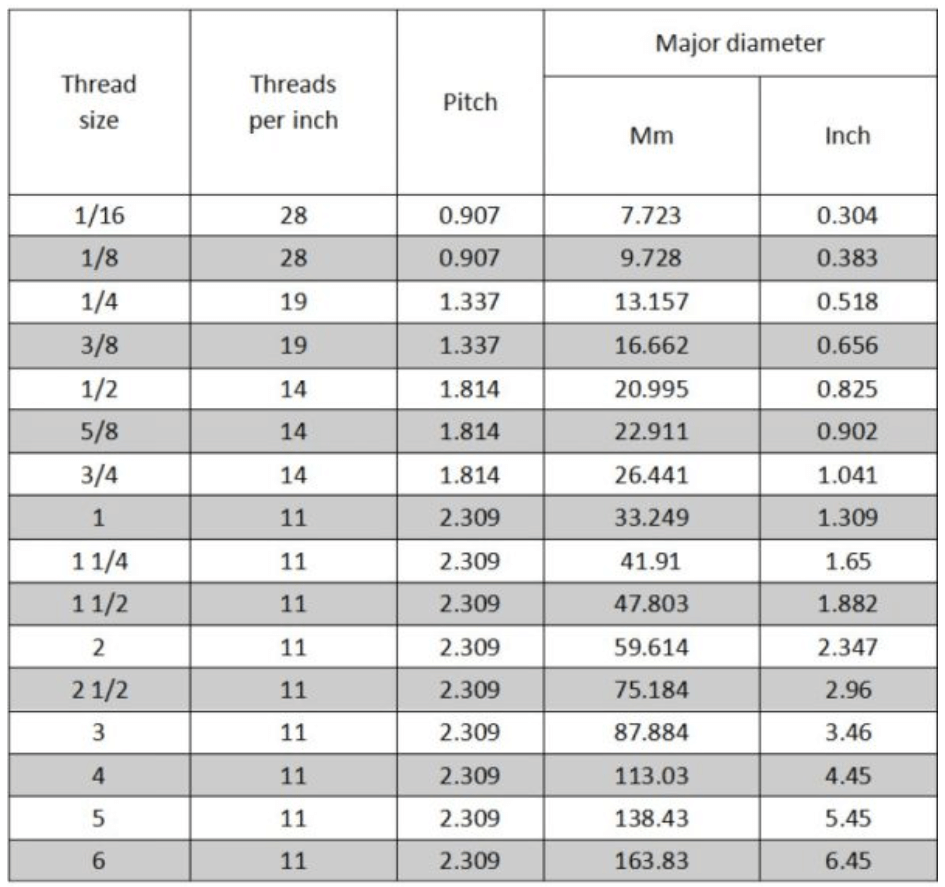

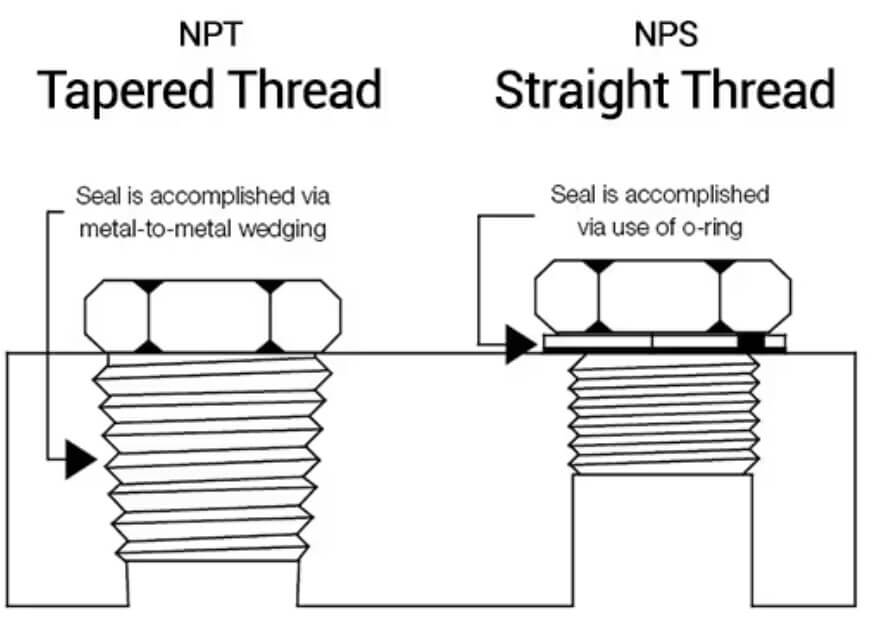

NPT (National Pipe Taper Thread) threads have a 60-degree thread angle and are tapered threads designed to form a tight seal for a variety of applications. The taper of the threads provides a stronger fit and is suitable for high-pressure applications. However, NPT threads typically require sealing compound or PTFE tape to ensure a leak-proof connection. They are commonly used in plumbing, industrial manufacturing, and oil and gas exploration.

NPT threads also have a derivative thread, NPTF threads. NPTF threads improve the thread standard and sealing than NPT threads. Therefore, NPTF provides a stronger seal and a more secure connection.

NPS(National Pipe Straight Thread) threads are straight rather than tapered. This design is not as self-sealing as NPT threads, so a gasket or washer is usually required for sealing. NPS threads are typically used in applications that do not require a leak-proof seal, such as some low-pressure applications or where a jam nut is used to secure the connection. The straight thread design makes them more suitable for connections that require frequent disassembly and reassembly with less risk of thread wear.

BSP vs NPT

BSP and NPT threads differ in geographical usage, thread forms, angles, and pitches. While NPT threads are prevalent in North America, BSP threads are the standard across other regions. Their incompatibility emphasizes the importance of precise selection, as mismatches can lead to leakage or failure.

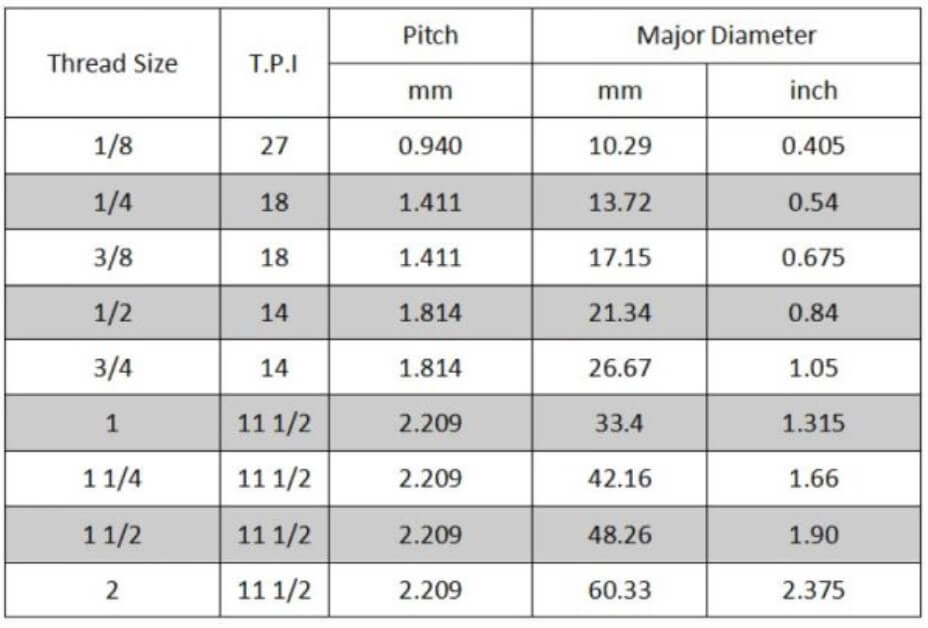

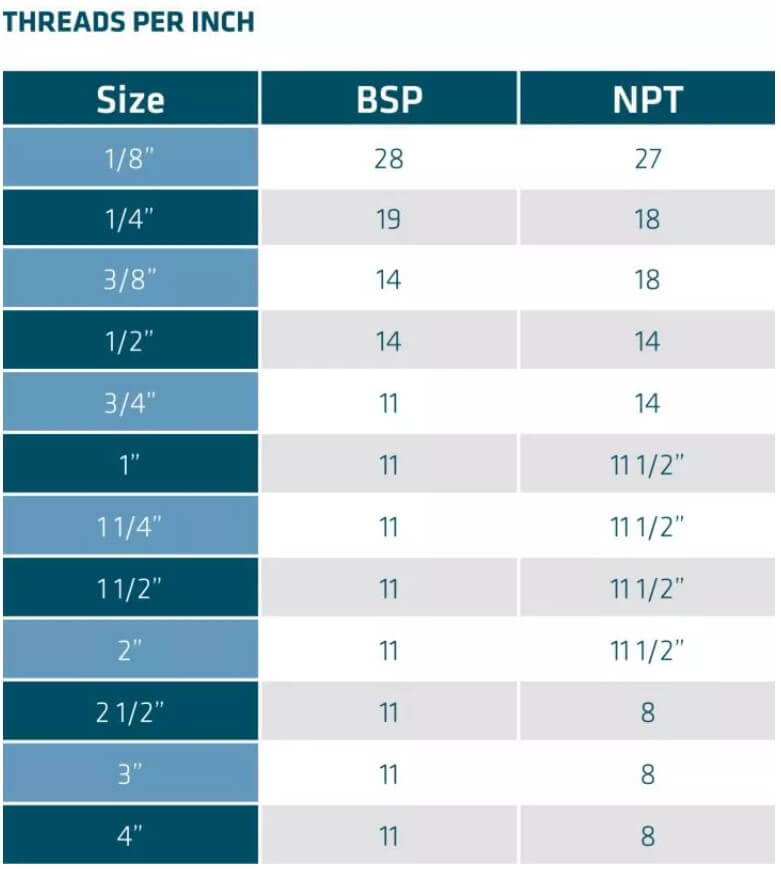

- BSP & NPT Thread Compatibility Chart

- The shape of the threads. With BSP, the peaks and valleys of the threads are rounded. In NPT, they are flat and sharp.

- The cut angle of the thread. BSP threads are cut at 55 degrees, while NPT are cut at 60 degrees.

QC Hydraulics has the capacity to produce all kinds of NPT and BSP thread fittings. If you have a difficulty to find the correct fittings in your applications, please contact our sales team to get the professional help.