Choosing the right hose for a hydraulic assembly is absolutely critical to ensure the assembly functions properly and safely.To select the proper hose, you must determine the necessary reinforcement. The reinforcement is the muscle of all hydraulic hoses, and determines the working pressure of your hose. Looking closer at the reinforcement layer, there are two primary design types to go with – braided or spiral design. The question is, braided hydraulic hose vs spiral hydraulic hose, which is better?

Read on to learn about them and their best applications. Finally, you will be able to choose the right hose for your hydraulic system.

What is a Braided hydraulic hose?

Wire braided hydraulic hose reinforcement layer incorporates one or two high tensile criss-crossing steel wires, the outer layer typically features abrasion, weather, and ozone-resistant synthetic rubber material. In addition, most braided hydraulic hoses come with oil-resistant synthetic rubber inner tubes.

Since the braided hydraulic hose has a smaller bend radius, it is more flexible than a standard hydraulic hose. Braided hydraulic hoses are relatively popular in different markets around the world. This is mainly because they are great for a wide variety of applications. Also, they are usually produced with premium materials, which makes them durable.

What is a Spiral hydraulic hose?

Spiral-wound hose consists of two or more sets of high-strength steel wire helically wound for typical strength, making the hose very strong, but also very rigid. The resistance to pressure peaks is very high, especially compared to braided hose. However, bend radius is affected and spiral wound hose is highly resistant to bending. Common spiral hydraulic hoses consist of four- or six-layers of spiral steel wires, the final product looks very heavy and rigid and more similar to a metal pipe. but it can endure high-pressure ratings and be used in high-impulse hydraulic systems. However, note that the inner diameter determines how much pressure a spiral hydraulic hose can withstand. A standard spiral hydraulic hose can reach up to 2300 to 6500 PSI WP. Similarly, they can reach up to 24940 PSI BP.

Spiral hoses have superior longevity as they boast superior strength and resistance to abrasion and damage compared to braided hoses. They are about four times more durable.

What are the differences between braided hydraulic hoses and spiral Hydraulic Hoses?

1.Construction

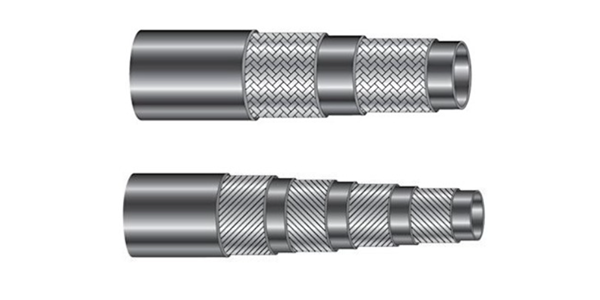

The biggest difference between spiral hose and braided hose is the construction of their reinforcements, which gives the two hoses a different appearance.

In spiral hoses, various steel wires are similarly wrapped around the inner tube to create reinforcement. The process of making spiral hose is faster than braided hose.

In braided hose, a criss-cross pattern is created by weaving various steel wires around the inner tube to form reinforcements. Unlike spiral hoses, the manufacturing process of braided hoses is a bit complicated due to their design.

2.Flexibility

The spiral hose is composed of multiple layers of steel wire and is very rigid. This hose does not bend easily because it is less flexible.

Braided hose is very flexible due to its interlocking design. You can bend this hose easily.

3.Durability

Spiral hose is more durable than braided hose. Over time, due to various changes in pressure levels and continuous use, braided hose loses tensile strength and the tightness between the wires begins to weaken. At the same time, the spiral hose has a higher resistance due to its various steel wire layers, making it more durable.

Conclusion:

If the application of the hose requires high flexibility, then a braided hose is better than a spiral hose. If you want a hose with long-lasting high pressure capabilities, then spiral hose is better than braided hose because of its reinforced structural design. And choose a hose based on its durability, then spiral hose is better than braided hose. Due to its enduring high pressure capabilities, spiral hoses are more durable and good for the long run.

QC Hydraulics as one of leading manufacturer of stainless steel hydraulic hose fittings, one-piece style and two-piece style are all available. Both styles can work well with braided hose and spiral hose. Please contact our team and tell us what kind of hose you used, then we will recommend you correct hose end fittings.