What is O-ring face seal fitting?

O-ring face seal is also called ORFS, as per SAE J1453 and ISO 8434 3 standard. As the name implies, ORFS, or (O-ring face seal) fittings incorporate an O-ring at the face of the fitting. ORFS connections are commonly manufactured in carbon, nickel plated carbon & stainless steel and typically use Buna-n or Viton, 90 durometer O-rings that seat into a groove in the face of the fitting.

What is O-ring boss seal fitting?

SAE Straight Thread O-ring or O-Ring Boss (ORB) is a multipurpose thread ideal for medium and high-pressure hydraulic applications. The male thread contains an O-ring at the base which mates with a chamfer machined into the female counterpoint, which makes this thread type ideal for non-leak applications.

What is the difference between ORFS and ORB fittings?

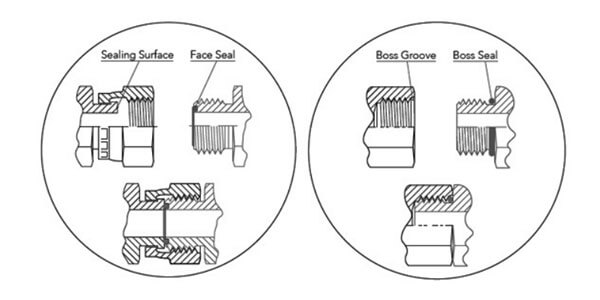

Both face sealing and boss sealing fitting types utilize an encapsulated O-ring in order to create a seal. the difference is that face seal fittings have the O-ring located in the grooved area at the end of the male thread, while boss seal fittings have the O-ring located at the base of the male thread. The corresponding female Face Seal fitting has a flat sealing surface that engages the O-ring in the male fitting and compresses it as the fittings are threaded together and creates a seal. Boss Seal female fittings on the other hand have a grooved “boss” before the first thread that acts to encapsulate the O-ring on the male thread thereby creating a seal.

Please contact our sales team to get more details about our O-ring face seal and O-ring boss seal hydraulic adapters.