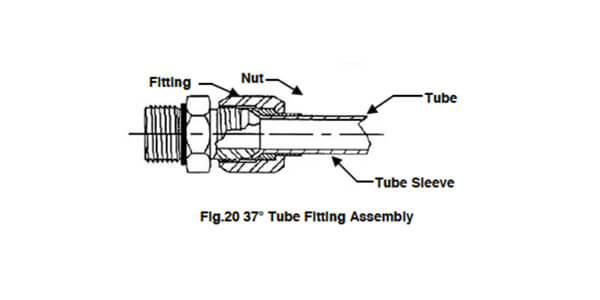

What is the 37 degree flare

A 37-flare fitting is an excellent pressure fitting having a broad selection of styles & shapes and is very extensively used all over the globe. Main features that call for its use are its simplicity, compactness in design, ease of assembly, high reliability, easy availability & global acceptance. These flare fittings can also be used as hose adapters.

The basic design is simple, which uses a flared tube end to hold & seal the medium under pressure. Main construction consists of three pieces: the body, sleeve & nut. The end of the tube is flared to 74 degrees included angle and held in between the body nose and the sleeve with a nut on top of them, thus resulting in a very effective seal between the fittings and the flared tube.

Straight flare fitting are normally manufactured from cold drawn bar stocks and all angular fittings from forgings. This kind of forged construction results in very close grain structure and also gives high reliability to the fitting eliminating all possibilities of leakage and can withstand high pressures with numerous makes and remakes even under severe operating conditions.

Also these fittings can be easily used in both metric and inch tubing’s. One single 37 degree fitting body can take both metric and inch tubes just by change in sleeves. The nuts used are the same, so the cost of the component comes down drastically and also the inventory.

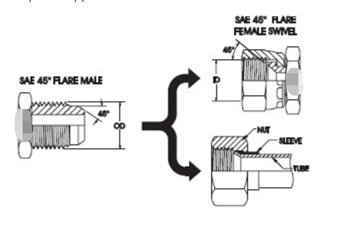

What is the 45 degree flare

SAE 45 degree fittings are a type of fare fittings machined with a 45 degree flare seating surface. SAE 45° flare connections are commonly used in automotive applications as well as military and oil gas industry. SAE fittings are typically made from steel and stainless steel. SAE and AN/JIC connections are incompatible due to the different flare angle.

If you have any demand of 37 degree flare and 45 degree flare hydraulic fittings, please contact QC Hydraulics.